CIRCULAR SOLUTIONS

Mountains of plastic waste on land and in the water are a major problem in many countries. Plastic waste is considered worthless. We are changing this: We are giving mixed plastic waste a new value!

We support national and international organisations in setting up circular economy initiatives. Our expertise is the production of versatile recycling boards for the local reuse of mixed plastic waste.

This is our contribution to the reduction of global plastic pollution and CO 2 emissions: plastic waste is no longer incinerated, landfilled or disposed of somewhere, but converted into multi-purpose boards which can also be recycled again.

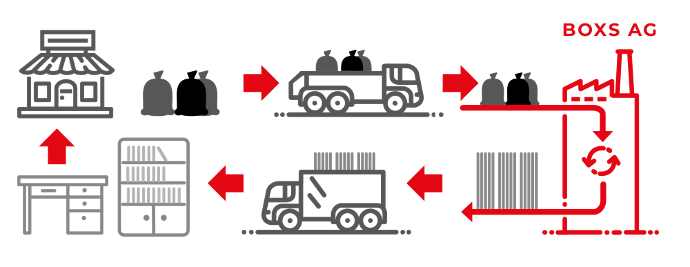

In this way, a closed cycle can be created:

Mixed plastic waste is reused.

Our offering

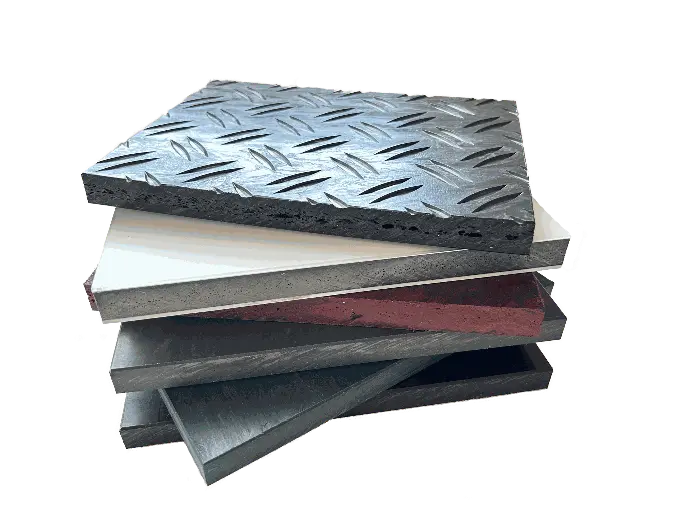

Our recycled boards are made from up to 100% recycled plastic waste. We mainly use the following plastic waste that cannot be separated economically: Packaging material (multilayer films), PE (polyethylene), PP (polypropylene), PS (polystyrene). We source our materials from post-consumer and post-industrial cycles.

Our products are:

High quality

- Weather resistant

- Rot proof

- Moisture repellent

- Easy to clean

economical

- Long product lifecycle

- Resistant (oils, alkalis, acids and saltwater)

- Easy to process (drilling, sawing, milling, screwing, CNC processing etc.)

- Versatile for indoor and outdoor use

sustainable

- Made from up to 100% mixed plastics and recycled milling materials

- Use of innovative and efficient production technology

- Reduction of CO₂ emissions through material reuse (prevention of burning)

- At the end of their lifespan, the boards can be returned to the production cycle: a closed material cycle

- Free from resins and adhesives

Interested? Order your

Sample of our recycled boards.

Our production technology

We have our own patented technology for the production of the boards:

Serial production

With this factory, high volumes of mixed plastic waste are processed energetically and efficiently into recycled boards using an industrial process.

The factory produces the boards in the format 2.44 x 1.22m. Depending on the application, the thickness can be set between 10 and 40mm.

One facility (dependent on setting)

– produces approx. 100‘000 m2 recycled boards/year

– recycles up to 1‘600 t plastic waste/year

– thus saves approx. 3‘300 t CO2/year

R & D Department

Recycled boards made from mixed plastic waste require an exact recipe to obtain the desired qualities. For this purpose, we have our laboratory and our R&D facility at our disposal.

The production process of the R&D facility corresponds to serial production. This means that recipes and tests can be run at a proportion of 1:4.

The boards produced can be used for a variety of end usage applications, some examples:

- Construction boards for the maintenance of existing residential infrastructure such as floor , partitions, doors, shutters, etc.

- Furniture boards for the production of benches, tables, shelves, school furniture, etc.

- Garden construction panels for raised beds, water collection systems, etc.

- The production of completely new accommodation is also possible: BOXShelter

Our projects

PLASTIC WASTE IN THE BUILDING ENVELOPE

Plastic waste pollution is omnipresent. BOXShelter uses plastic waste to construct the building envelope. Thus, the system not only provides adequate and safe shelter for people in need, but also contributes to improving the environment by combating plastic pollution and promoting recycling.

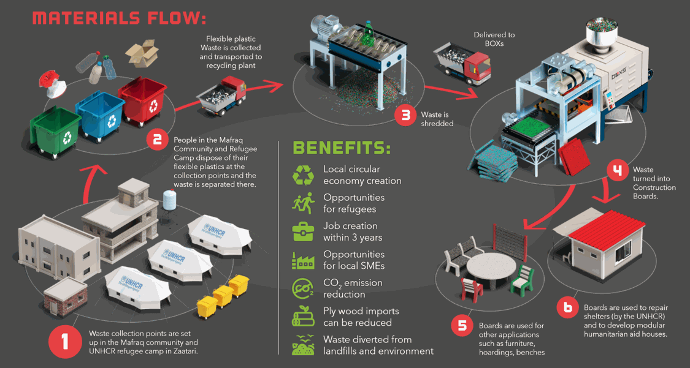

CIRCULAR ECONOMY PROJECT IN JORDAN

As a member of the project "Tadweer" in Jordan, we are developing a production facility for the local manufacture of recycled plastic boards from local plastic waste to improve the infrastructure.